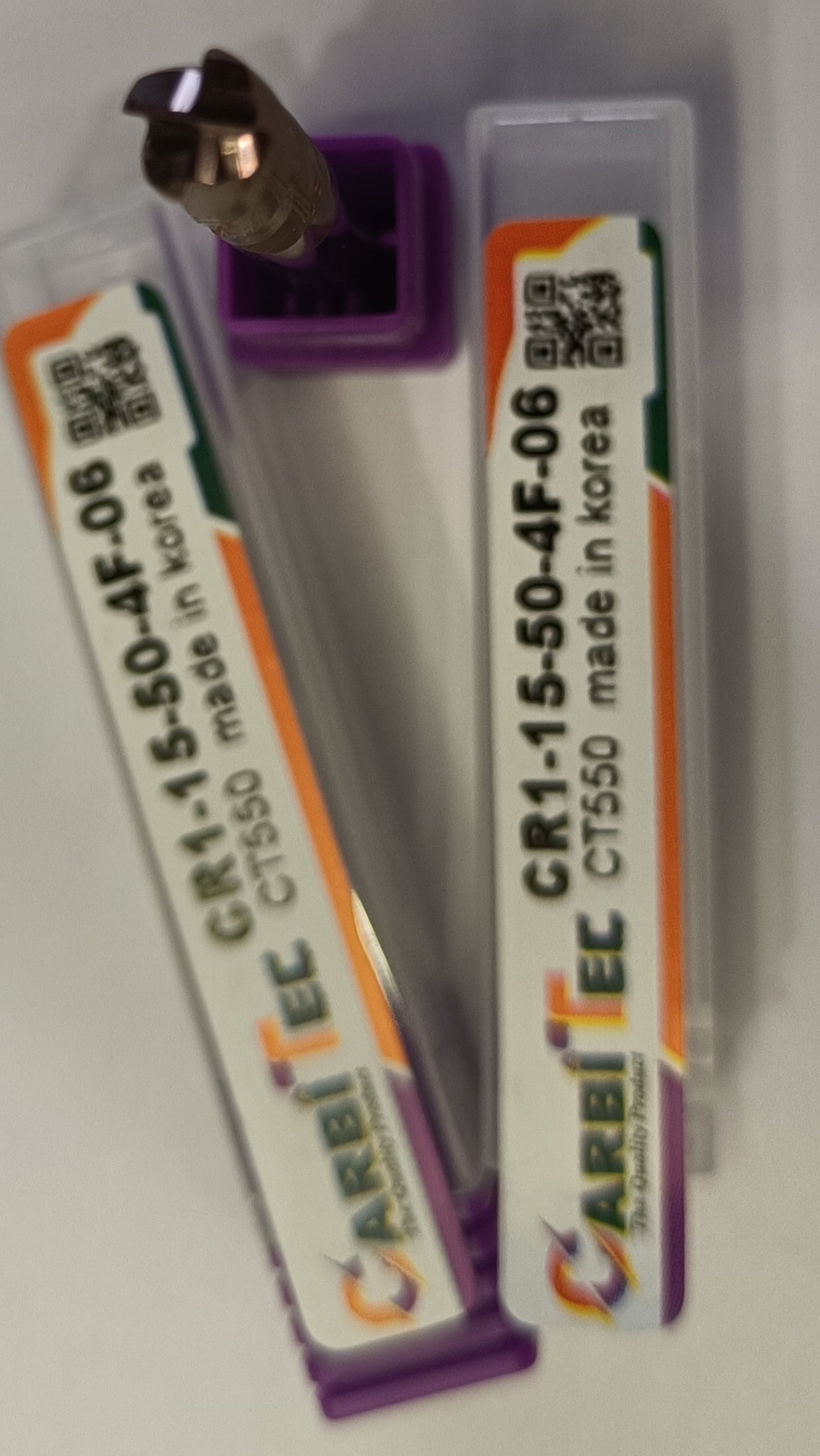

Corner Radius End Mill

Ask a question

Estimate delivery times: 12-26 days (International), 3-6 days (United States).

Return within 30 days of purchase. Duties & taxes are non-refundable.

Guaranteed Safe Checkout

Corner Radius End Mill

Recommended Corner‑Radius End Mills 4‑Flute,

-

30° helix,

-

Perfect for light roughing/finishing with strengthened edges for improved lifespan.

3. Carbide Corner Radius

-

Stub-length (1″ flute), corner radius adds durability—ideal for robust pocket finishing India‑Available CARBITEC Series

-

Ø 6 mm , 4‑Flute, 55HRC,

-

Technical Insights

-

Coatings & Materials: Options span uncoated, TiAlN — suitable for a wide range of steels, cast iron, stainless, and non-ferrous materials

-

Helix & Flute Design: 30° helix provides balanced performance. Variable index and unequal-pitch designs minimize chatter and improve finish

-

Corner Radius Benefit: Rounded corners significantly strengthen the cutting edge and extend tool life—effective starting radius ~0.005" for small cutters

Choosing the Right Tool

| Diameter | Corner Radius | Coating | Best For |

|---|---|---|---|

| 6 mm | ~0.5 – 1 mm equivalent | TiAlN | Pocket finishing, general milling in steel/non-ferrous |

Best Practices

-

Depth vs. Radius: Ensure both axial and radial depths ≥ corner radius to avoid rubbing and premature wear

-

Coolant Strategy: Always use flood or mist—coatings hold up with or without coolant, but coolant extends tool life

-

Minimize Overhang: Keep tool extensions short to avoid deflection and maximize finish quality.

-

Toolpath Setup: Combine roughing passes with smaller-corner cutters followed by finishing passes with larger radius for smooth transitions.

| Size |

6*50 |

|---|