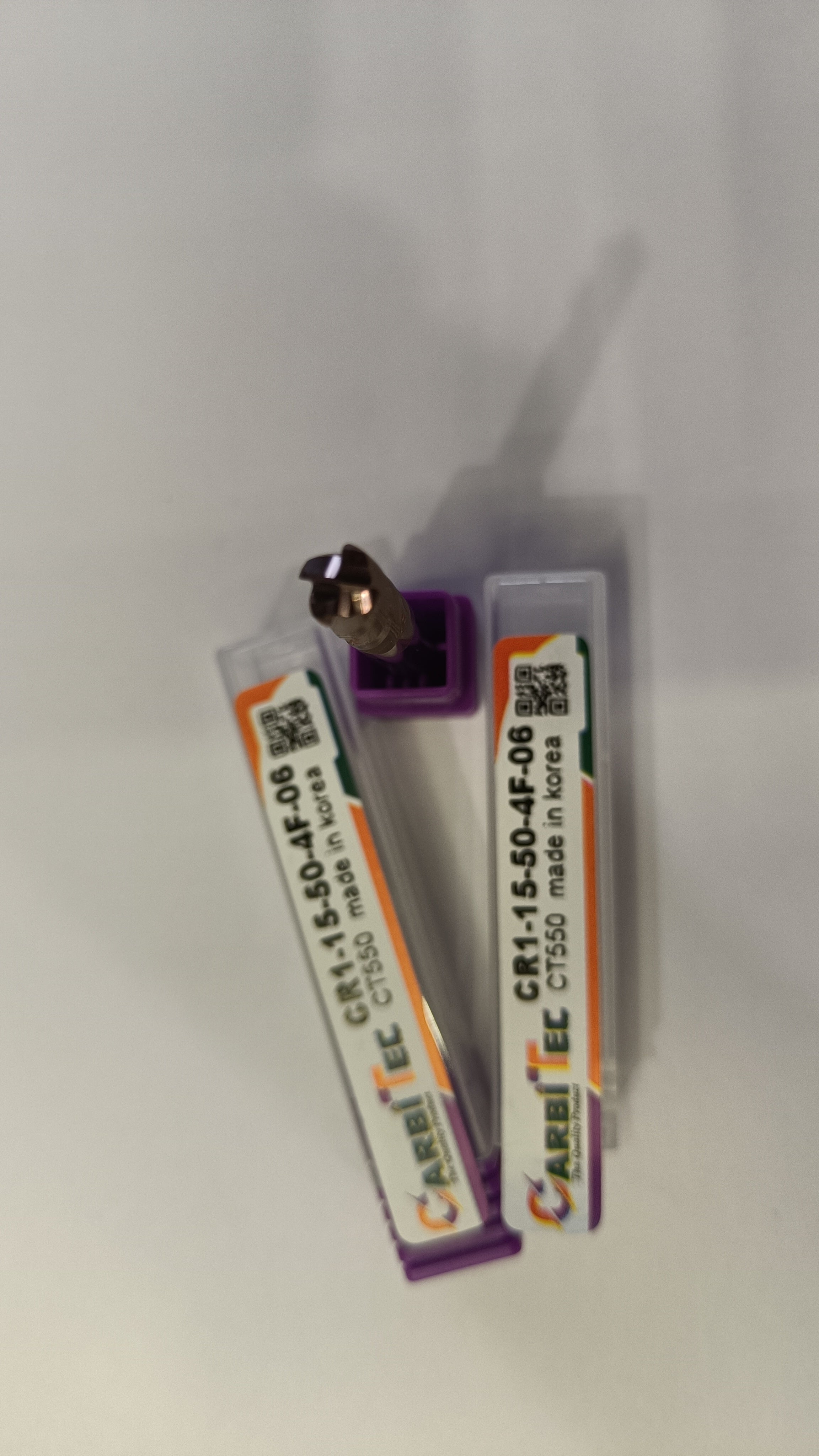

END MILL

Ask a question

Estimate delivery times: 12-26 days (International), 3-6 days (United States).

Return within 30 days of purchase. Duties & taxes are non-refundable.

Guaranteed Safe Checkout

END MILL

6 mm Corner Radius End Mill – Key Specifications

| Feature | Value |

|---|---|

| Cutting Diameter | 6.00 mm |

| Corner Radius Options | 0.2 mm / 0.5 mm / 1.0 mm |

| Flutes | 4 (for general and semi-finishing) or 6 (for finishing) |

| Helix Angle | 35°–45° |

| Length of Cut (LOC) | ~15–18 mm |

| Overall Length (OAL) | ~50–60 mm |

| Shank Diameter | 6.00 mm |

| Material | Solid micrograin carbide |

| Common Coatings | AlTiN, TiAlN, WXS, or X-Coating (heat-resistant) |

4 Specific 6 mm Corner Radius End Mills 1. Helical Solutions – H40ALV-CR Series

-

Diameter: 6.00 mm

-

Corner Radius: 0.5 mm

-

Flutes: 4

-

Helix Angle: Variable (40°–42°)

-

Length of Cut: 18 mm

-

OAL: 60 mm

-

Coating: Aplus (AlTiN-based)

-

Application: Stainless steel, titanium, high-temp alloys

Designed for aggressive machining with smooth surface finish and long tool life.

2. Harvey Tool – 4-Flute Corner Radius for Hardened Steels

-

Diameter: 6.00 mm

-

Corner Radius: 0.2 mm

-

Flute Length: 12 mm

-

Overall Length: 50 mm

-

Shank: 6 mm

-

Coating: AlTiN

-

Application: Hardened tool steel (up to 65 HRC), stainless

Ideal for tight-tolerance work in hard materials.

3. YG-1 V7+ INOX Corner Radius End Mill

-

Diameter: 6.00 mm

-

Corner Radius: 0.5 mm

-

Flutes: 4

-

Helix Angle: 45°

-

Coating: X-Coating (AlCrN)

-

Use: Stainless, Inconel, titanium, duplex steel

High-performance cutter for heat-resistant materials and aggressive feeds.

4. OSG EXOCARB® WXS-CRE

-

Diameter: 6.00 mm

-

Corner Radius: 1.00 mm

-

Flute Length: 15 mm

-

Overall Length: 60 mm

-

Coating: WXS (high hardness & thermal stability)

-

Material Suitability: Hardened steel, tool steel, mold steel

Recommended Machining Parameters (6 mm, AlTiN)

| Material | RPM | Feed/Tooth | Feed Rate | Radial DOC | Axial DOC |

|---|---|---|---|---|---|

| Tool Steel (HRC 50–55) | 9,000–12,000 | 0.015–0.025 mm | 540–1,200 mm/min | 0.4–1.0 mm | 1.5–3.0 mm |

| Stainless Steel | 7,000–10,000 | 0.012–0.02 mm | 340–800 mm/min | 0.3–0.8 mm | 1.0–2.0 mm |

| Aluminum (w/ uncoated) | 12,000–16,000 | 0.025–0.045 mm | 1,200–2,400 mm/min | 1.0–2.5 mm | 2.0–4.0 mm |

Tip: Choose a larger corner radius (like 1 mm) for better edge strength in roughing or interrupted cuts. Use smaller radius (like 0.2 mm) for precision finishing.

Would you like:

-

Direct supplier links (Harvey, Helical, YG-1, OSG)?

-

PDF datasheets?

-

Cutting data optimized for your CNC or material?

Let me know — happy to help you pick the best one.